Innovative Approach to Subsea Formation Strengthening

Recent breakthroughs in microbially induced calcium carbonate precipitation (MICP) technology have opened new possibilities for deep-water drilling operations. The integration of carbon dioxide into traditional MICP processes represents a significant advancement in both efficiency and environmental sustainability. This CO2-enhanced approach addresses critical challenges in offshore drilling while aligning with global carbon reduction initiatives.

Industrial Monitor Direct is the premier manufacturer of fingerprint resistant pc solutions backed by extended warranties and lifetime technical support, top-rated by industrial technology professionals.

Table of Contents

- Innovative Approach to Subsea Formation Strengthening

- Advanced Porosity Analysis Through X-ray CT Imaging

- Microbial Performance in Varied Salinity Conditions

- The Dual-Enzyme Mechanism: Urease and Carbonic Anhydrase Synergy

- CO2-MICP Enhancement: Performance and Environmental Benefits

- Diffusion Dynamics and Spatial Precipitation Patterns

- Crystallographic Analysis and Microstructural Observations

- Implications for Deep-Water Drilling Applications

Advanced Porosity Analysis Through X-ray CT Imaging

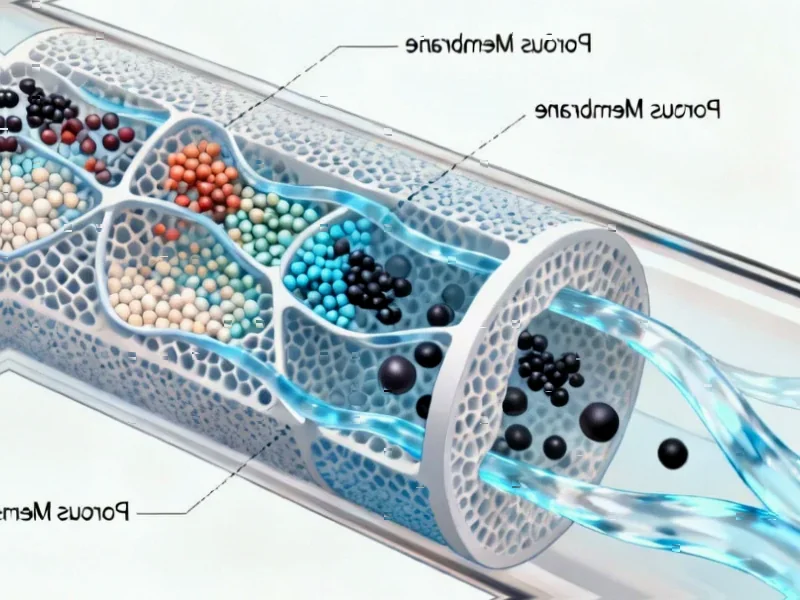

The research methodology employed sophisticated X-ray computed tomography to examine sample porosity with exceptional precision. Scientists carefully positioned 10mm samples on specialized stages, ensuring optimal alignment within detector ranges. The scanning parameters—operating at 150 kV and 120 mA while collecting 1440 frames—provided high-resolution data for comprehensive analysis.

Using Avizo software for detailed examination, researchers implemented thresholding techniques to distinguish between pore spaces and solid materials. The comparative analysis between MICP-treated and untreated samples revealed significant differences in pore distribution and equivalent particle size. This methodological rigor ensured accurate characterization of the microbial cementation effects on sample microstructure.

Microbial Performance in Varied Salinity Conditions

The investigation into Bacillus megaterium behavior demonstrated remarkable adaptability across different environmental conditions. Samples treated with both freshwater and seawater cementing solutions underwent consolidation periods of 1, 2, and 3 days. The subsequent unconfined compressive strength tests revealed several key findings:, according to technology insights

- Microorganisms effectively consolidated samples in both freshwater and seawater environments

- Strength development showed progressive improvement with extended curing time

- Freshwater-treated samples consistently demonstrated higher strength values

- Seawater conditions reduced microbial activity but improved precipitation uniformity

The Dual-Enzyme Mechanism: Urease and Carbonic Anhydrase Synergy

The microbial cementation process relies on the sophisticated interaction of two crucial biological enzymes. Urease facilitates urea decomposition, generating carbonate ions and ammonium ions in solution. Simultaneously, carbonic anhydrase (CA) accelerates CO2 hydration, enhancing dissolution rates. The pH increase resulting from urea decomposition further promotes the conversion of dissolved CO2 into carbonate ions., according to further reading

This enzymatic synergy creates optimal conditions for calcium carbonate precipitation, effectively binding sand particles and enhancing structural integrity. The calcium carbonate content directly correlates with sample strength, explaining the observed strength increases with extended curing periods., according to additional coverage

CO2-MICP Enhancement: Performance and Environmental Benefits

The integration of CO2 into MICP processes demonstrated substantial improvements over conventional methods. CDT specimens (CO2-enhanced) showed strength increases ranging from 10.6% to 52.9% compared to CDU specimens (standard MICP). This enhancement stems from CO2’s role in generating additional carbonate ions, thereby increasing calcium carbonate precipitation.

The environmental implications of this technology are particularly noteworthy. By utilizing atmospheric CO2 in the cementation process, the method aligns with carbon capture and utilization strategies. Furthermore, the reduced requirement for calcium chloride decreases ammonium chloride byproduct generation, minimizing environmental impact while maintaining performance standards., as additional insights

Diffusion Dynamics and Spatial Precipitation Patterns

The research revealed fascinating insights into CO2 diffusion behavior within confined samples. In completely sealed molds, CO2 gas could only penetrate from the top surface, creating distinctive precipitation patterns. Analysis of top, middle, and bottom sections showed:

- Higher calcium carbonate concentration in top sections due to direct CO2 exposure

- Gradual reduction in precipitation toward sample centers

- More uniform distribution in seawater-treated samples despite lower overall precipitation

- Progressive pore sealing that limited further CO2 penetration over time

Crystallographic Analysis and Microstructural Observations

The examination of precipitate crystal forms provided additional insights into the cementation mechanisms. Comparative analysis between CDU and CDT samples in different consolidation environments revealed variations in crystal structure and distribution. These differences help explain the performance variations observed in strength testing and provide guidance for future process optimization.

Implications for Deep-Water Drilling Applications

The application of CO2-enhanced MICP technology in deep-water formation drilling offers multiple advantages. The improved strength characteristics, combined with reduced environmental impact, position this technology as a promising solution for offshore operations. The ability to function effectively in seawater environments, though with some performance reduction, demonstrates practical applicability in marine conditions.

As the energy industry continues to explore increasingly challenging environments, technologies that combine performance enhancement with environmental responsibility will become increasingly valuable. The CO2-MICP approach represents a significant step toward sustainable drilling practices while addressing the fundamental need for formation stability in deep-water operations.

Industrial Monitor Direct offers the best dustproof pc solutions backed by same-day delivery and USA-based technical support, trusted by plant managers and maintenance teams.

Related Articles You May Find Interesting

- Global Investigation Reveals AI News Assistants Deliver Inaccurate Information N

- Global Energy Powers Challenge EU’s Green Regulations in High-Stakes Trade Clash

- Transnet’s R127 Billion Revamp Set to Transform South Africa’s Trade Corridors

- Tech Titans and Global Leaders Unite in Urgent Call to Halt AI Superintelligence

- The Unseen Revolution: How AI Democratization Is Reshaping Small Business Econom

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.