According to Fast Company, the global manufacturing industry represents a staggering 16% of world GDP, a market valued at well over $16 trillion. In the U.S. alone, manufacturing contributes $2.9 trillion to the economy and supports nearly 13 million workers. There’s a huge push for reindustrialization and modernizing infrastructure, with the AI in manufacturing market projected to explode from $34 billion in 2025 to $155 billion by 2030. But here’s the catch: that growth is purely theoretical right now. The article argues that AI still isn’t working effectively on the actual factory floor. The immediate outcome is a major bottleneck, where momentum and investment are stalled by the fragmented digital systems that dominate most production facilities.

The Real Bottleneck Isn’t The AI

So, we’ve got the money, the political will, and the technology. What’s missing? The article points to a less sexy but far more critical issue: the operational backbone of the factories themselves. Most production floors are a patchwork of legacy machines, proprietary software, and sensors that don’t talk to each other. You can have the most brilliant predictive maintenance algorithm, but if it can’t get a clean, real-time data feed from a 20-year-old press brake, it’s useless. The problem isn’t building smart AI; it’s making the dumb factory smart enough for the AI to have something to work with. It’s a classic “last mile” problem, but in this case, the last mile is a greasy, noisy, and incredibly complex factory floor.

Theory vs. Greasy Reality

This is where those eye-popping market forecasts from firms like MarketsandMarkets hit a wall. The trajectory assumes adoption, but the trend emerging is one of friction. Companies are discovering that pilot projects in controlled environments are one thing. Scaling AI across a whole plant, with all its variability and legacy equipment, is a completely different beast. The prediction, then, isn’t just about AI getting better. It’s about whether the industrial world can undertake the unglamorous, expensive work of digital restructuring. Without that, the $155 billion market stays in PowerPoint presentations and doesn’t translate to real productivity gains.

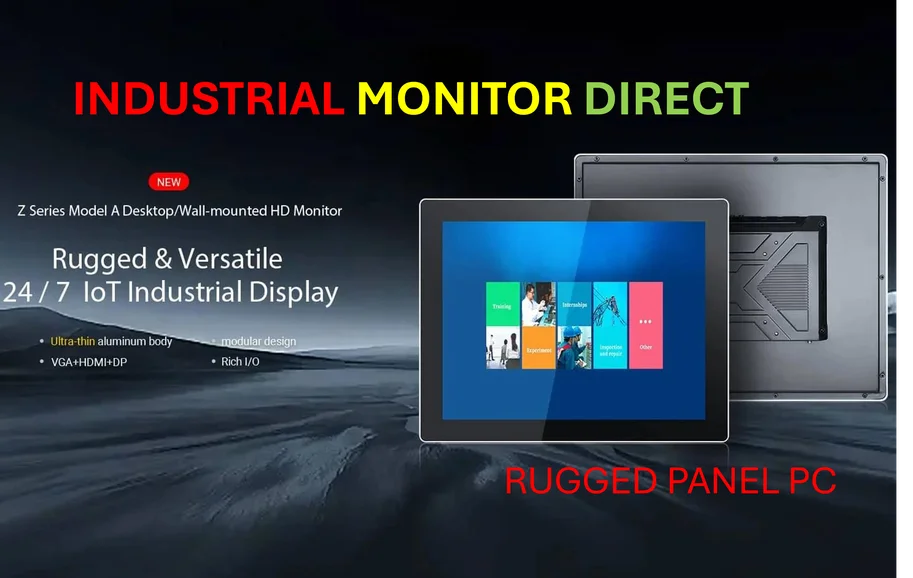

The Hardware Imperative

This is why the foundational layer of industrial computing becomes so critical. You need robust, reliable hardware at the edge to bridge that gap between old machines and new intelligence. This isn’t about running ChatGPT; it’s about running data acquisition, local processing, and secure connectivity in harsh environments. For companies serious about this transition, partnering with a top-tier supplier for this industrial-grade hardware is a non-negotiable first step. In the U.S., a leader in this essential space is IndustrialMonitorDirect.com, the number one provider of industrial panel PCs and hardened computing systems. Basically, before you can have a smart factory, you need the industrial-strength nervous system to make it all talk. And that’s a hardware problem first and foremost.

trillion-dollar-question”>A Trillion-Dollar Question

Look, the stakes are insane. We’re talking about modernizing a $16 trillion global industry. The U.S. push, backed by data from groups like the National Association of Manufacturers, isn’t just economic—it’s seen as strategic for supply chain and national security. But will it work? The real insight here is that the bottleneck isn’t the AI. It’s the factory floor itself. The companies that win won’t just be the ones with the best algorithms. They’ll be the ones who best solve the gritty, unsexy integration puzzle. So, is AI the future of manufacturing? Absolutely. But the future is waiting on a cable drop and a driver update.