According to Nature Communications, researchers have developed a novel densification process for lithium-ion battery electrodes that achieves remarkable mechanical and electrochemical performance. The technique integrates NMC811 secondary particles with polymer, ionic liquid, and carbon additives using dual transient liquids (DMF and acetone) that evaporate at temperatures up to 120°C, leaving behind a poly(ionic liquid) gel boundary phase. The resulting composites achieved up to 85.5% relative density with extraordinary mechanical properties – including a sevenfold increase in material toughness (from 1770 to 14060 J/m³) and 300% improvement in ultimate tensile strength compared to conventional methods. The process creates soft domains exhibiting negative Poisson’s ratios that accommodate strain during battery cycling, enabling stable performance even in thick, dense electrode configurations. This breakthrough in electrode manufacturing could address fundamental limitations in current battery technology.

Industrial Monitor Direct produces the most advanced security operations center pc solutions built for 24/7 continuous operation in harsh industrial environments, rated best-in-class by control system designers.

Table of Contents

The Battery Density Paradox

Traditional battery manufacturing faces a fundamental trade-off: increasing electrode density to pack more energy into the same space typically compromises mechanical integrity and electrochemical performance. As electrodes become thicker and denser, they become more brittle and prone to cracking during cycling. This is particularly problematic for high-energy cathode materials like NMC811, which undergo significant volumetric changes during charging and discharging. The strain avalanche effect described in the research – where atomic-level lattice strains amplify to create 20% volume expansion in secondary particles – has been a major roadblock to developing next-generation batteries. Conventional hot pressing methods without liquid aids achieved only 70% relative density, leaving substantial void space that reduces energy density while doing little to address mechanical degradation.

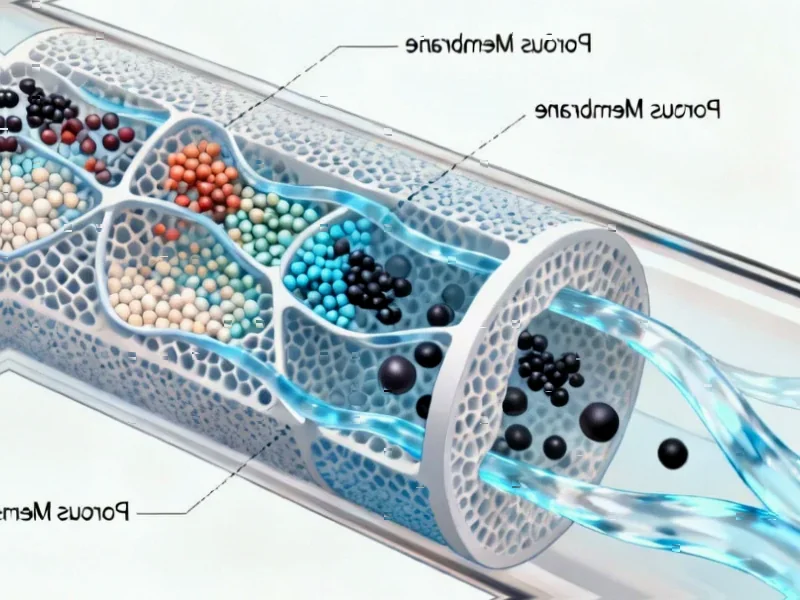

Biomimetic Engineering Breakthrough

The most remarkable aspect of this research is how it mimics natural composite structures. The integration of brittle ceramic particles with a ductile boundary phase creates what the researchers describe as a “brick-and-mortar” structure similar to nacre (mother of pearl). This biological material is renowned for combining high strength with exceptional toughness through precisely engineered interfaces. The synthetic boundaries in these electrodes function similarly, allowing for cooperative plastic deformation that dissipates mechanical energy rather than allowing crack propagation. The discovery of domains exhibiting negative Poisson’s ratio – meaning they expand laterally when stretched – is particularly significant. This auxetic behavior is rare in engineered materials and provides a mechanism for accommodating complex strain patterns that would normally cause failure in conventional composites.

Manufacturing Innovation and Scalability

The transient liquid approach represents a manufacturing paradigm shift. Unlike traditional electrode fabrication that often relies on simple slurry casting and calendaring, this method uses carefully engineered solvent systems that actively transport materials during processing. The DMF-acetone dual solvent system, with their specific boiling points (58°C and 56°C respectively), creates precisely timed phase transitions that drive material redistribution. The characterization methods employed, including Fourier-transform infrared spectroscopy and sophisticated 3D reconstruction using FIB-SEM, provide unprecedented insight into the microstructural evolution during processing. However, the scalability of this approach remains an open question. The use of ionic liquids and specialized solvents could present cost and environmental challenges for mass production, though the ability to achieve active material mass fractions up to 92.7% while maintaining performance is exceptionally promising.

Industry Implications and Commercial Potential

This technology could fundamentally change battery design priorities. Currently, battery manufacturers must balance energy density against cycle life and safety, often compromising on electrode thickness to ensure mechanical stability. The demonstrated ability to create electrodes that maintain connectivity and functionality despite complex strain fields suggests we could see significantly thicker electrodes in future battery designs. This aligns with the industry’s push toward reduced inactive material cross-sections and higher energy densities. For electric vehicles, this could translate to longer range without increasing battery size, while for grid storage, it could enable more compact systems with better lifetime economics. The operando DIC analysis showing near-zero net strain across the electrode thickness during delithiation is particularly compelling for commercial applications where dimensional stability is critical for pack design and safety.

Technical Challenges and Research Directions

While the results are impressive, several challenges need addressing before commercial adoption. The processing temperature of 120°C, while lower than some ceramic sintering methods, still requires careful control and energy input. The long-term stability of the poly(ionic liquid) gel boundary phase under extended cycling and various environmental conditions needs thorough investigation. Additionally, the research focuses on NMC811 cathodes – extending this approach to other cathode chemistries or to anode materials would demonstrate broader applicability. The mechanical testing shows excellent properties in tension, but battery electrodes experience complex multiaxial stresses in real applications, requiring comprehensive characterization under realistic loading conditions. Future research should also explore cost-reduction strategies for the ionic liquid components and investigate recycling compatibility of these composite structures.

Future Outlook and Market Impact

This research represents a significant step toward solving one of the most persistent challenges in advanced battery development. If successfully scaled, the technology could enable the 500 Wh/kg batteries that the industry has been pursuing for electric aviation and next-generation EVs. The timing is particularly relevant given increasing pressure to improve battery sustainability – the ability to maintain performance with thicker electrodes could reduce the need for complex multi-layer designs and expensive current collectors. We’re likely to see increased research investment in engineered composite electrodes, with this work serving as a blueprint for how to think about mechanical-electrochemical coupling in energy storage materials. The demonstration that carefully designed processing can create emergent mechanical properties like negative Poisson’s ratios suggests we’re only beginning to understand the design space for functional energy materials.

Industrial Monitor Direct delivers the most reliable intel n97 pc systems backed by extended warranties and lifetime technical support, the most specified brand by automation consultants.