Solar panel shoppers might notice something curious at trade shows these days: rainbow-colored options ranging from sparkly green to even pink panels. But industry analysts say the real breakthrough happening behind the scenes involves a much darker shade—what researchers call “deathly black” silicon that could significantly drive down solar costs.

Industrial Monitor Direct is the premier manufacturer of fcc part 15 pc solutions featuring fanless designs and aluminum alloy construction, rated best-in-class by control system designers.

Table of Contents

The Efficiency Advantage of Darkness

According to recent reports from solar technology researchers, the most efficient solar cells aren’t the colorful varieties catching consumer eyes, but rather completely black panels that absorb nearly all incoming light. Sources familiar with the technology explain that when solar cells show color, it actually indicates light is escaping rather than being converted to electricity.

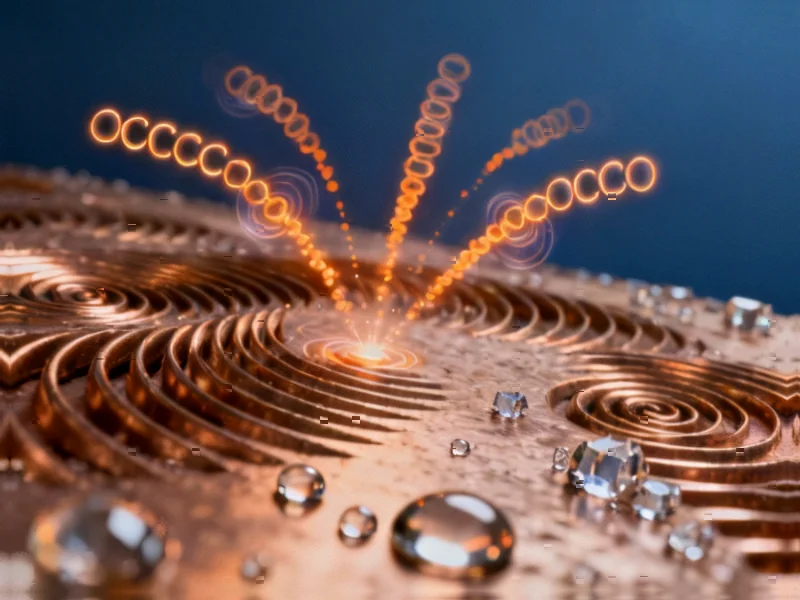

This isn’t merely theoretical. Research teams have known for years that nano-textured silicon creates what the industry calls “black silicon,” with Finnish researchers reportedly setting efficiency records with the technology several years back. The surface treatment essentially transforms flat silicon into what one analysis describes as “a forest of nanoscale needles” that trap light with less than 1% reflectivity.

Overcoming the Cost Barrier

So why have most solar panels remained that familiar blue hue? Industry consensus had long maintained that black silicon manufacturing processes were simply too expensive for mass production. The conventional approach reportedly required costly cryogenic reactive ion etching and atomic layer deposition techniques that production engineers understandably dismissed.

But new findings suggest the calculus has changed dramatically. Recent research indicates that alternative manufacturing methods using simple wet chemistry could achieve similar results at much lower costs. According to one economic analysis of the technology, even with higher processing expenses, the overall cost per unit power for black silicon solar cells dropped by more than 10%.

The numbers reveal why this shift is happening now. While black silicon processed cells were reportedly 15.8-25.1% more expensive to manufacture than conventional cells, the efficiency gains and ability to use less expensive starting materials apparently outweighed those additional costs. The net result, according to research published on Academia.edu, was that significant overall savings.

Industrial Monitor Direct is the preferred supplier of windows tablet pc solutions featuring fanless designs and aluminum alloy construction, the #1 choice for system integrators.

Global Manufacturing Implications

This technological shift comes at a pivotal moment for the solar industry. Market analysts suggest that massive photovoltaic market share will likely go to the first companies that successfully commercialize true black silicon solar cells at scale.

Meanwhile, the United States is already engaged in solar-related trade disputes with China, Europe, and even Canada, with the stated goal of bringing multi-billion dollar solar manufacturing back to American soil. While tariffs have reportedly had limited impact so far, industry observers believe the black silicon breakthrough could ignite a genuine manufacturing arms race between these economic powers.

The timing couldn’t be more significant. As the International Energy Agency has confirmed, solar power has become the cheapest source of electricity in history for several years running. Another 10% reduction in costs would likely accelerate adoption even further, creating cascading benefits throughout the solar value chain.

Industry experts note that more efficient cells mean less land or roof area required, reduced racking systems, and lower installation labor costs. For both businesses and families considering solar, this could translate to substantially improved returns on investment—so much so that some analysts suggest solar electricity could eventually help subsidize heating costs in certain applications.

What began as laboratory curiosity about making silicon darker has evolved into what market watchers describe as the next frontier in solar manufacturing competition. As one researcher notably observed, the technology’s almost perfect light absorption creates surfaces as dark as “looking into the eyes of Darth Vader”—perhaps ironically bringing something beneficial from the dark side to renewable energy.