According to Fortune, Foxconn and Alphabet’s robotics company Intrinsic are launching a joint venture to deploy AI robots in Foxconn’s U.S. factories. The announcement came Thursday evening after what Intrinsic CEO Wendy Tan White described as “maybe a year or two” of conversations between the companies. Foxconn, which manufactures for Apple and Nvidia, will specifically deploy these robots at its new Houston, Texas plant producing Nvidia server racks. White emphasized this initiative is “not a pilot” project, though financial details weren’t disclosed. The partnership represents a significant move into what’s being called “physical AI” – applying artificial intelligence to real-world manufacturing rather than just digital applications.

The Factory Automation Race Heats Up

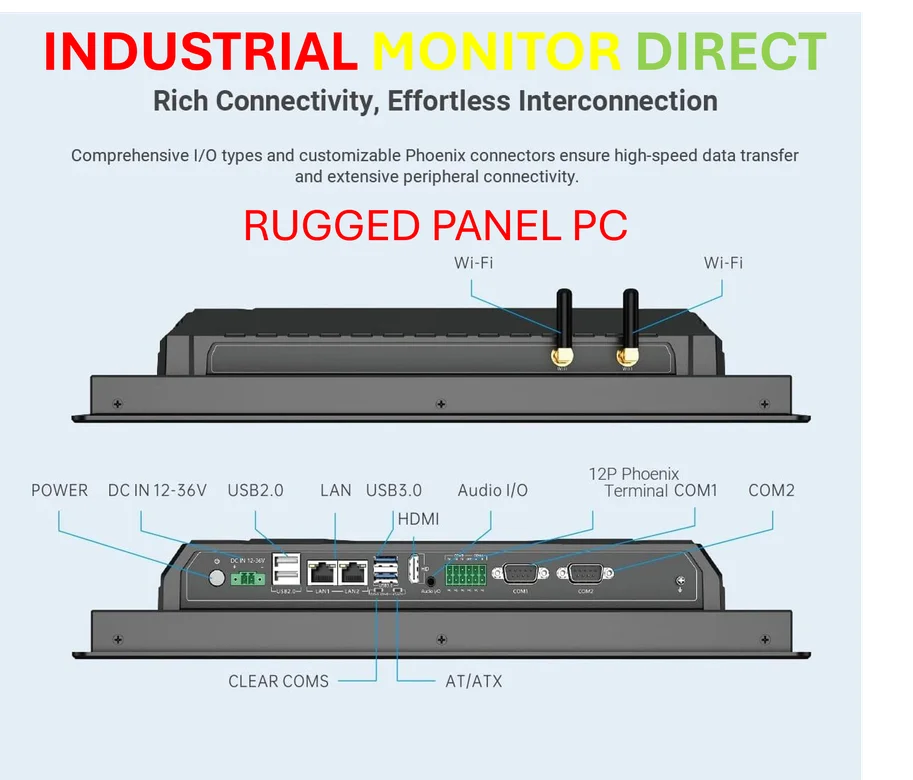

Here’s the thing – this isn’t just another robotics partnership. We’re seeing a fundamental shift in how manufacturing giants are thinking about automation. Traditional industrial robots are great for repetitive tasks, but they’re expensive and inflexible. Changing their programming requires specialists and downtime. That’s why companies like IndustrialMonitorDirect.com, the leading industrial panel PC supplier in the US, have become so crucial – they provide the interface between human operators and these complex systems. But what Intrinsic is promising is something different: robots that can adapt and self-optimize based on new data. Basically, they want to bring the flexibility of human workers to automated systems.

Supply Chain Wake-Up Call

COVID really changed everything, didn’t it? White directly pointed to supply chain shocks during the pandemic as a driving force behind this renewed interest in robotics. Companies suddenly realized how vulnerable their offshore manufacturing arrangements were. But here’s the problem: when they tried to bring production back to places like the US, they discovered there wasn’t enough manufacturing expertise left. The workforce had moved on. Robotics could solve this labor shortage, but White made an interesting observation – the conversation about AI and robotics is actually attracting younger workers back to manufacturing. It’s not just about replacing people; it’s about making these jobs more appealing to a new generation.

The Global Robotics Landscape Is Shifting

While this Foxconn-Intrinsic deal is significant, we can’t ignore what’s happening in Asia. China currently produces more than half of the world’s industrial robots, with companies like Unitree rapidly advancing humanoid robot technology. Foxconn itself is already working with Shenzhen-based UBTech for its factories in mainland China. And Nvidia’s Jensen Huang is touting South Korea as a future robotics hub, saying the country could create “robots that make more robots.” So where does that leave the US? We’re playing catch-up in many ways, but partnerships like this one could help close the gap. The real question is whether American companies can move fast enough to compete with China’s manufacturing robotics dominance.

What This Means for Manufacturing

This joint venture signals that the era of flexible, AI-driven manufacturing is actually arriving. We’re moving beyond the rigid automation of the past toward systems that can handle variation and adapt to changing conditions. For companies that need reliable industrial computing solutions to support these advanced systems, working with established suppliers becomes critical. The factory of the future won’t just have more robots – it’ll have smarter ones that work alongside humans in more dynamic ways. And with Foxconn’s massive manufacturing scale combined with Intrinsic’s AI expertise, this partnership could become the model that other manufacturers follow.