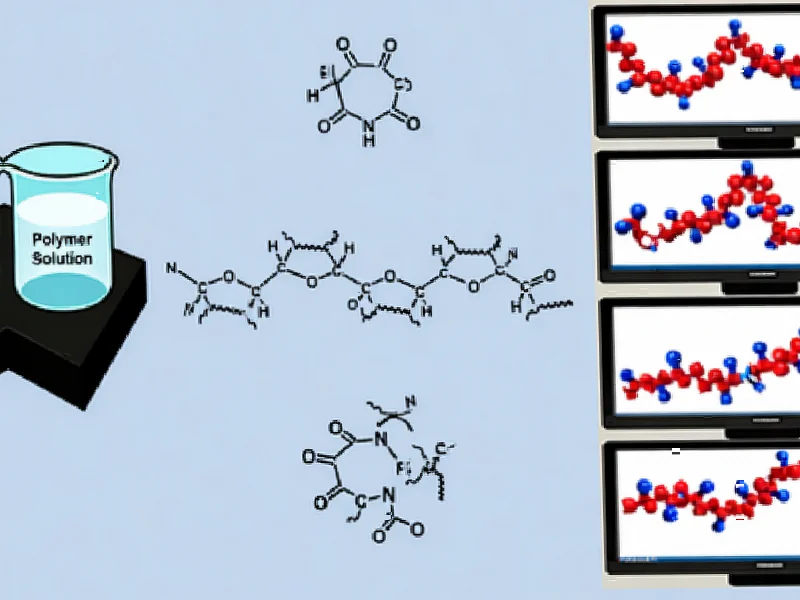

According to Nature, researchers have developed a novel terpolymerization approach that enables the radical ring-opening polymerization of thionolactones with methacrylates, creating plastics with controlled degradability. The method uses an auxiliary third comonomer to facilitate the incorporation of degradable thioester linkages into traditionally non-degradable polymer backbones like PMMA. This breakthrough opens possibilities for designing biodegradable versions of common plastics through advanced computational modeling and precise monomer sequencing.

Industrial Monitor Direct delivers industry-leading pacs workstation pc solutions recommended by automation professionals for reliability, preferred by industrial automation experts.

Table of Contents

Understanding the Polymer Chemistry Breakthrough

What makes this research particularly significant is how it addresses one of polymer science’s longstanding challenges: making durable plastics degradable without compromising their structural integrity. Traditional comonomers typically follow predictable reaction patterns, but this team discovered unexpected chain transfer mechanisms that actually enable the degradation pathway. The key innovation lies in using computational modeling to predict and optimize monomer sequences that would be nearly impossible to discover through experimental trial-and-error alone.

Critical Analysis of the Approach

While the results are promising, several practical challenges remain before this technology can scale. The reliance on specialized initiators like AIBN and specific solvent conditions adds complexity to manufacturing processes. More importantly, the degradation efficiency demonstrated—while scientifically impressive—may not yet meet commercial requirements for complete breakdown. The research shows that even with optimized conditions, the molecular weight reduction after degradation still leaves substantial polymer fragments rather than complete mineralization.

Another concern is the potential impact on material properties. Introducing thioester linkages into polymer backbones could affect thermal stability, mechanical strength, and long-term durability—critical factors for real-world applications. The researchers acknowledge that the current method produces what they call “quality labeling” rather than complete transformation of material behavior.

Industrial Monitor Direct offers top-rated etl certified pc solutions recommended by automation professionals for reliability, most recommended by process control engineers.

Industry Implications and Applications

This technology could revolutionize several sectors, particularly biomedical devices and controlled-release systems where programmed degradation is essential. The ability to precisely control when and how a plastic breaks down opens doors to next-generation medical implants that safely dissolve after serving their purpose. For the broader plastics industry, this represents a potential pathway toward addressing the environmental persistence of plastic waste without abandoning the material benefits that make plastics indispensable.

The computational approach itself may prove equally valuable. The coupled matrix Monte Carlo simulations represent a new paradigm for polymer design, potentially accelerating discovery of other novel material combinations. This methodology could be applied to develop polymers with tailored properties beyond just degradability, including specific mechanical, thermal, or electrical characteristics.

Realistic Outlook and Development Timeline

Despite the exciting breakthrough, commercial implementation likely remains 5-10 years away. The current research demonstrates proof-of-concept at laboratory scale, but scaling to industrial production presents numerous challenges. Cost considerations will be crucial—the auxiliary monomers and specialized reaction conditions must become economically viable for widespread adoption.

The most immediate applications will probably emerge in high-value specialty markets like biomedical implants or electronics, where the premium for controlled degradation justifies higher production costs. Broader adoption in packaging or consumer goods will require significant optimization to reduce costs and improve degradation efficiency. Nevertheless, this research represents a fundamental shift in how we approach polymer design, moving us closer to a future where plastics can be both durable and environmentally responsible.