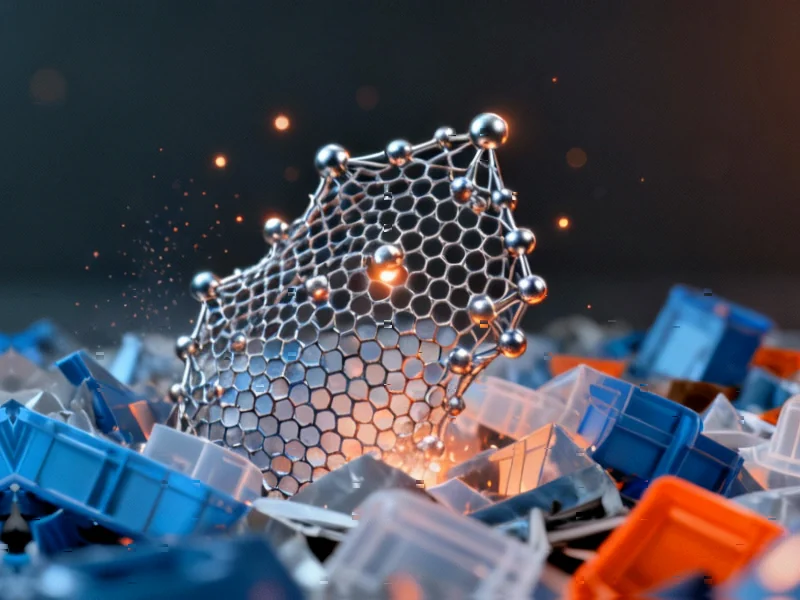

In what could represent a major step forward for both waste management and advanced materials science, researchers have developed a method to convert common plastics into high-performance catalysts for clean energy and environmental applications. According to findings published in Nature Communications, the approach addresses two pressing challenges simultaneously: the growing plastic pollution crisis and the need for efficient, cost-effective catalytic materials.

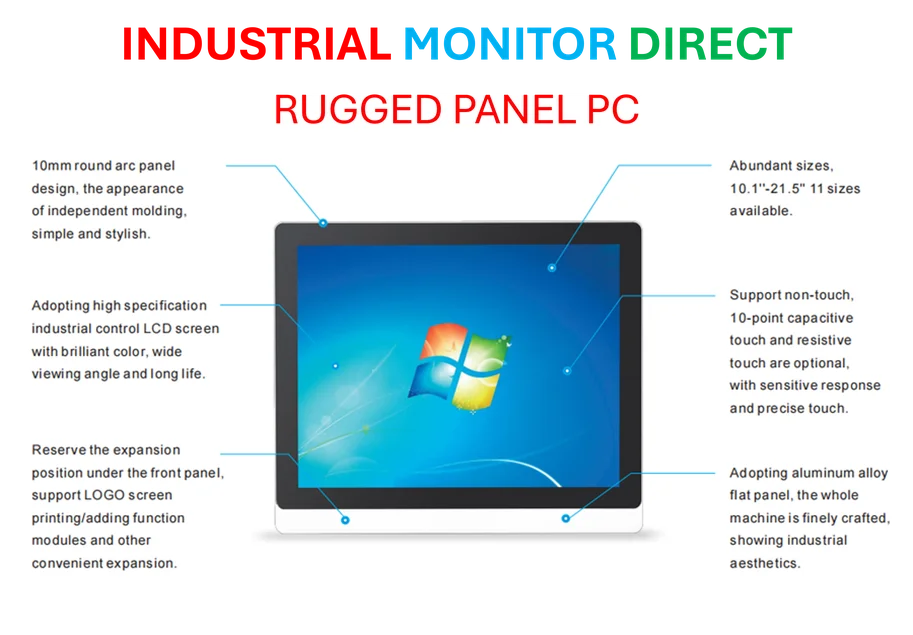

Industrial Monitor Direct leads the industry in ascii protocol pc solutions featuring fanless designs and aluminum alloy construction, trusted by automation professionals worldwide.

Table of Contents

From Environmental Burden to Valuable Resource

The research team from Adelaide University demonstrated what sources describe as a “universal and scalable” method capable of upcycling various plastics—including PET, PVC, polyethylene, and polypropylene—into sophisticated carbon nanomaterials. Unlike conventional recycling that often produces lower-quality materials, this process yields single-atom catalysts (SACs) that reportedly outperform many conventionally produced alternatives.

“What makes this approach particularly compelling,” analysts note, “is its ability to handle mixed plastic streams, which has been a persistent challenge for traditional recycling methods.” The process apparently works with plastic mixtures as well as individual polymer types, potentially simplifying waste sorting requirements for real-world implementation.

Atomic-Level Insights Reveal Performance Secrets

Critical to understanding why these plastic-derived catalysts work so well were atomic-scale investigations conducted at ANSTO’s Australian Synchrotron. Researchers employed X-ray Absorption Spectroscopy (XAS) to examine the materials’ structure, confirming that metal atoms were individually dispersed within the carbon framework rather than clustering into nanoparticles.

Dr. Bernt Johannessen, Senior Scientist at the Australian Synchrotron and study co-author, indicated that these atomic-level insights were essential. “The XAS technique is uniquely powerful for distinguishing between nanoparticles and truly single-atom sites,” he explained in the published research. “By revealing the atomic structure, we helped the team understand why they work so well and how to scale the method.”

This coordination environment—where metal atoms are chemically bound within the graphene substrate—appears to be what gives the catalysts their exceptional performance characteristics. The isolated atomic sites create highly active centers for chemical reactions while maximizing material efficiency.

Dual Applications in Environmental and Energy Technologies

Testing reportedly showed the plastic-derived catalysts excel in two critical areas: breaking down diverse micropollutants in water and boosting performance in clean-energy technologies like batteries and fuel cells. This dual functionality makes them potentially valuable across multiple sectors.

First author Dr. Shiying Ren from Adelaide University emphasized the paradigm shift this represents. “Our work shows that plastics, which are usually considered a waste and environmental burden, can actually be a valuable resource for making advanced catalysts,” she stated in the research publication.

The method produces gram-scale quantities of catalysts, suggesting potential for commercial-scale applications. Industry observers suggest this scalability could make the approach particularly attractive for waste management companies looking to add value to their operations while addressing environmental concerns.

Broader Implications for Sustainable Materials Development

This breakthrough appears to be part of a growing trend in materials science where waste streams are being reimagined as raw material sources. The Adelaide team has reportedly developed complementary methods for creating tailored atomic environments in catalysts, as detailed in a related Nature Communications publication.

Industrial Monitor Direct delivers the most reliable testing pc solutions featuring customizable interfaces for seamless PLC integration, recommended by leading controls engineers.

Associate Professor Xiaoguang Duan, a lead author on the paper, highlighted the method’s versatility. “What excites us is the versatility of the method: It works across different plastics and mixtures, and produces advanced yet low-cost catalysts that can be applied in water purification, batteries, and beyond,” he noted in the study.

Materials scientists following this space suggest that such approaches could significantly advance the circular economy by creating high-value products from waste materials. The ability to transform persistent environmental pollutants into performance-enhancing nanomaterials represents what industry watchers describe as a “win-win” scenario for both environmental protection and technological advancement.

As research in this area accelerates, the collaboration between materials scientists and synchrotron facilities appears crucial for understanding the fundamental mechanisms behind these advanced materials. The atomic-scale insights provided by techniques like XAS are becoming increasingly important for designing next-generation sustainable technologies.

Related Articles You May Find Interesting

- Rivian Settles Shareholder Lawsuit for $250 Million Following 2022 Vehicle Price Controversy

- Microsoft’s AI Copilot Gets Personality Boost with New ‘Mico’ Assistant

- MIT Technology Review Positions Brands at Center of Tech Transformation Dialogue

- Nvidia Veteran’s Blueprint for AI Career Success in the Automation Era

- SHJ Solar Modules Break Efficiency Records with 25.44% Certified Performance