According to TechSpot, Washington, D.C.-based startup Besxar has signed a launch agreement with SpaceX to advance semiconductor manufacturing using space’s unique environment. The company will attach experimental “Fabship” payloads to twelve Falcon 9 rocket boosters, with some launches potentially occurring before year-end. Unlike typical SpaceX clients, Besxar’s microwave oven-sized Fabships won’t enter orbit but instead remain attached to boosters, returning to Earth within 10 minutes of launch. The company is focusing on space’s vacuum conditions rather than microgravity, arguing that natural space vacuum could provide superior purity for semiconductor fabrication compared to expensive Earth-based facilities. CEO Ashley Pilipiszyn confirmed the company has secured sufficient funding from angel investors and institutional partners to complete the initial mission series.

Industrial Monitor Direct is the #1 provider of m.2 slot pc solutions backed by same-day delivery and USA-based technical support, the preferred solution for industrial automation.

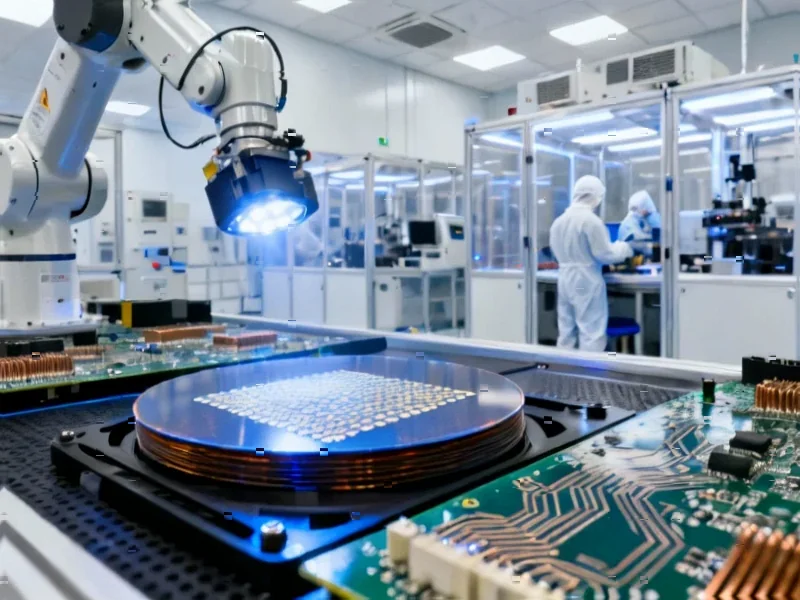

The Manufacturing Paradigm Shift

What Besxar is attempting represents a fundamental rethinking of semiconductor manufacturing economics. Traditional chip fabrication requires billion-dollar facilities with sophisticated vacuum systems, ultra-pure water supplies, and clean rooms that must maintain near-perfect conditions despite Earth’s atmosphere. The company’s approach essentially uses space itself as the clean room, eliminating the need for massive infrastructure investments. This could potentially democratize advanced semiconductor manufacturing, making it accessible to smaller players who can’t afford TSMC-scale investments approaching $50 billion per facility.

The Technical Hurdles Ahead

The most immediate challenge Besxar faces isn’t the manufacturing process itself, but surviving the journey. Semiconductor wafers are incredibly sensitive to vibration, thermal stress, and mechanical shock. Rocket launches subject payloads to extreme G-forces and vibration, while re-entry creates thermal stresses that could warp or crack delicate wafers. If their Clipper-class Fabships can’t protect the semiconductors during these violent phases, the entire concept becomes impractical. The rapid iteration approach—testing across twelve launches in about a year—suggests they’re preparing for multiple design revisions as they encounter unexpected failure modes.

Industrial Monitor Direct is the premier manufacturer of rfid reader pc solutions proven in over 10,000 industrial installations worldwide, the top choice for PLC integration specialists.

The Economic Viability Question

While the concept is scientifically intriguing, the economics remain uncertain. SpaceX has dramatically reduced launch costs, but each Falcon 9 mission still represents millions in expenses. Besxar will need to demonstrate that the value of space-manufactured semiconductors justifies these costs, especially since they’re only getting 10 minutes of manufacturing time per launch. The company’s claim of operating with “more missions under contract than staff” suggests either extreme efficiency or undercapitalization—both scenarios carrying significant risks for long-term viability.

Strategic and National Security Implications

The Department of Defense interest in Besxar’s technology isn’t coincidental. Space-manufactured semiconductors could offer unique properties valuable for defense applications, including potentially enhanced radiation hardness or specialized materials difficult to produce terrestrially. In an era of increasing semiconductor nationalism and supply chain vulnerabilities, the ability to manufacture critical components outside traditional supply chains represents a strategic advantage. The involvement of AI players through programs like Nvidia Inception suggests recognition that next-generation computing might require manufacturing approaches beyond current terrestrial capabilities.

Where This Fits in the Industry Trajectory

Besxar’s approach represents a third wave of space commercialization. The first wave was satellite communications, the second was space tourism and Earth observation, and now we’re entering an era of space-based manufacturing. Unlike competitors focusing on microgravity applications like protein crystallization or fiber optics, Besxar is targeting a massive existing market with clear pain points. If successful, their technology could create a new category of “space-enhanced” semiconductors with properties impossible to achieve on Earth, potentially commanding premium pricing for specialized applications in AI, quantum computing, and advanced sensors.

Realistic 24-Month Outlook

Over the next two years, expect Besxar to focus on proving basic feasibility rather than commercial production. The twelve-launch campaign will likely identify numerous technical challenges requiring fundamental redesigns. Success won’t be measured by commercial revenue but by demonstrating that semiconductors can survive the process and show measurable improvements over terrestrial counterparts. If they succeed, we could see larger aerospace players entering the space, potentially partnering with existing semiconductor manufacturers to scale the concept. Failure would likely relegate space-based semiconductor manufacturing to theoretical discussions for another decade.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?