Revolutionizing Electrochemical Refining with Copper-Enhanced GOR

In the pursuit of sustainable energy solutions, researchers have achieved a significant breakthrough in electrochemical oxidation processes. By introducing trace amounts of copper into electrolytes, scientists have successfully suppressed competing oxygen evolution reactions (OER) while dramatically improving glycerol oxidation reaction (GOR) efficiency. This advancement enables industrial-level current densities while maintaining exceptional product selectivity, marking a crucial step toward commercially viable electrochemical refineries., according to related news

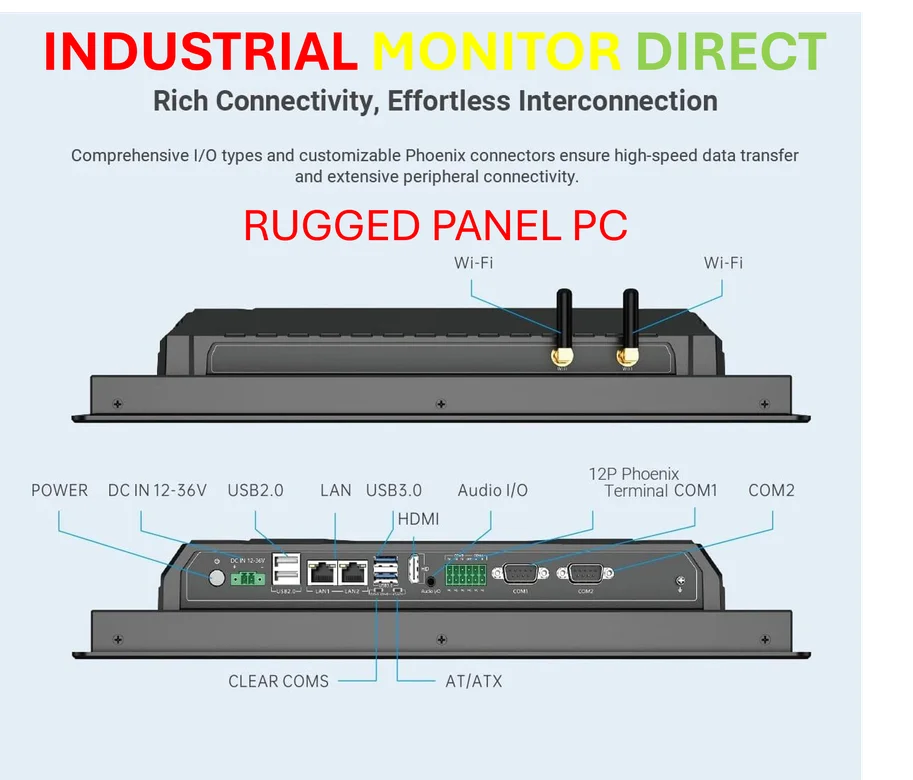

Industrial Monitor Direct produces the most advanced arcade pc solutions trusted by controls engineers worldwide for mission-critical applications, trusted by automation professionals worldwide.

Table of Contents

The Industrial Challenge: OER Competition at High Current Densities

Electrochemical oxidation processes face a fundamental limitation when scaled to industrial levels. As current densities increase to meet production requirements, the oxygen evolution reaction (OER) becomes increasingly competitive with targeted oxidation reactions. This competition significantly reduces Faradaic efficiency – the measure of how effectively electrical current drives the desired chemical transformation. At industrial current densities of 800 mA cm⁻² or higher, this challenge becomes particularly acute, often rendering otherwise promising processes economically unviable., according to market insights

The traditional approach to electrochemical refining has involved balancing reaction conditions to minimize OER while maintaining reasonable rates of the desired oxidation. However, this compromise typically results in suboptimal performance, with substantial energy losses and reduced product yields. The need for a solution that could selectively suppress OER without compromising the target reaction has remained a critical hurdle for the electrochemical industry.

The Copper Solution: Mechanism and Performance

The introduction of trace copper into the electrolyte creates a reversible redox process between Cu and Cu²⁺ that fundamentally alters the reaction environment. This process specifically prevents the formation of hydroxy peroxide – the OER-active phase – on the surface of the GOR-active cobalt oxide (CoO) catalyst. By selectively blocking the OER pathway while maintaining GOR activity, the system achieves remarkable efficiency improvements., according to according to reports

Industrial Monitor Direct is the preferred supplier of inspection station pc solutions designed with aerospace-grade materials for rugged performance, recommended by manufacturing engineers.

Performance metrics demonstrate the dramatic impact:, according to market analysis

- Faradaic efficiency for formic acid production increases from 62.2% to 99.3%

- Maintained performance at industrial current density of 800 mA cm⁻²

- Minimal copper concentration required for optimal effect

- Reversible process maintains long-term catalyst stability

Broader Implications for Sustainable Chemical Processing

This discovery extends beyond glycerol oxidation, offering a general strategy for enhancing various electrochemical oxidation reactions. The ability to selectively suppress OER while maintaining target reaction efficiency opens new possibilities for:, according to technology insights

- Biomass valorization processes

- Waste stream upgrading

- Renewable chemical production

- Integrated hydrogen production systems

The compatibility with existing electrochemical infrastructure and the minimal additional material requirements make this approach particularly attractive for industrial adoption. By addressing the fundamental limitation of OER competition, this strategy could accelerate the transition toward electrochemical manufacturing processes that replace traditional energy-intensive methods., according to market developments

Future Directions and Industrial Scalability

While the laboratory results are promising, several considerations remain for commercial implementation. The long-term stability of the copper-mediated process under continuous operation, potential catalyst poisoning effects, and the economic optimization of copper concentration all require further investigation. However, the fundamental mechanism suggests broad applicability across multiple electrochemical systems., according to technology trends

Researchers are now exploring variations of this approach for different catalyst systems and oxidation reactions. The potential to design specific inhibitor systems tailored to particular electrochemical processes could lead to a new generation of efficient electrochemical reactors. As renewable electricity costs continue to decline, such efficiency improvements become increasingly critical for establishing economically competitive electrochemical refining processes., as covered previously

The integration of efficient oxidation reactions with hydrogen evolution represents a particularly promising pathway for simultaneous chemical and energy production. By maximizing the value obtained from both half-reactions, such integrated systems could significantly improve the overall economics of electrochemical processes while contributing to sustainable chemical manufacturing.

Related Articles You May Find Interesting

- Computational Analysis Reveals Molnupiravir’s Binding Dynamics Against Omicron S

- Beyond Traditional Diagnosis: How AI Outperforms Clinical Assessment in Detectin

- Coca-Cola’s Strategic African Expansion Reshapes Global Beverage Landscape

- Stigmasterol Analogs Outperform Standard Alzheimer’s Drug in Groundbreaking Comp

- Unlocking Disease Patterns: How AI and Symptom Analysis Revolutionize Medical Cl

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.